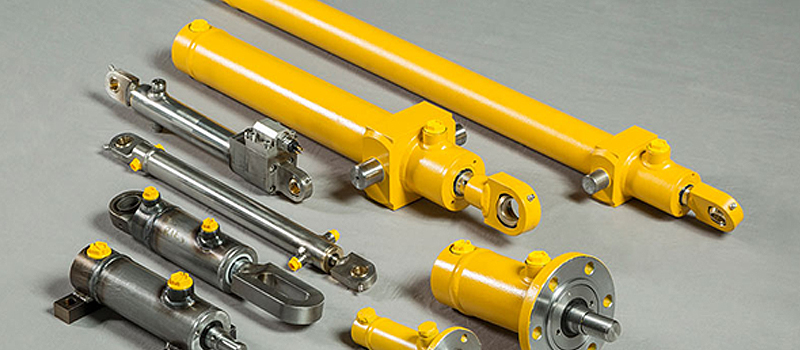

The hydraulic cylinder is probably the single most important part of any hydraulic ram, or hydraulic pump, for that matter. When your hydraulic cylinder starts to leak, you need to make sure that it’s repaired as soon as possible because without a properly functioning cylinder your whole system will cease to work properly.

These answers will come from your Hydraulic Ram Repairs Service or from your own hydraulic maintenance team.

However, if you’re not familiar with these devices, how do you know if the leakage you’re seeing is an indication of something more serious?

Tips on how to tell if your hydraulic cylinder is leaking and what steps you should take next:

Signs of a leak

Most hydraulic cylinder leaks can be detected by a few visible signs. The first sign of a leak is rust or discoloration on the exterior of the seal, but not all external rust or stains indicate that there is an internal leak.

These external indicators do, however, let you know that your Hydraulic Pumps may need replacement soon.

You should also check for oil seeping out from around the sealing areas on both ends and then dripping down onto the ground underneath it. Another possible sign of a hydraulic cylinder leak is foaming fluid being expelled from the spindle while operating it.

What are the common causes of leaks?

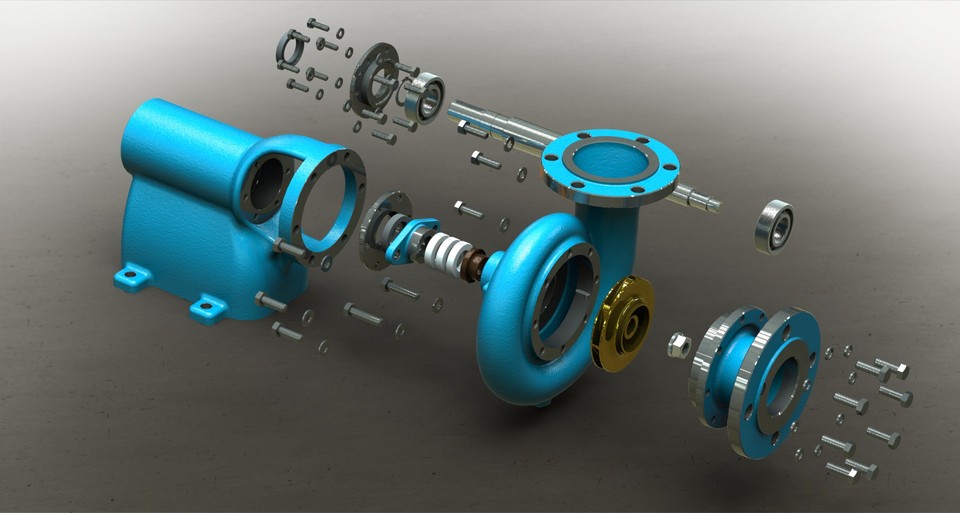

There are a number of causes for hydraulic cylinder leaks. The most common reasons include contamination or lack of oil, worn-out seals, stripped packing teeth, bad piston rings, internal corrosion or other mechanical damage.

An indication that you may have a leaking cylinder is the release of water. If you see bubbles in your oil as you’re filling up your tank, this also could indicate a leak that needs to be repaired.

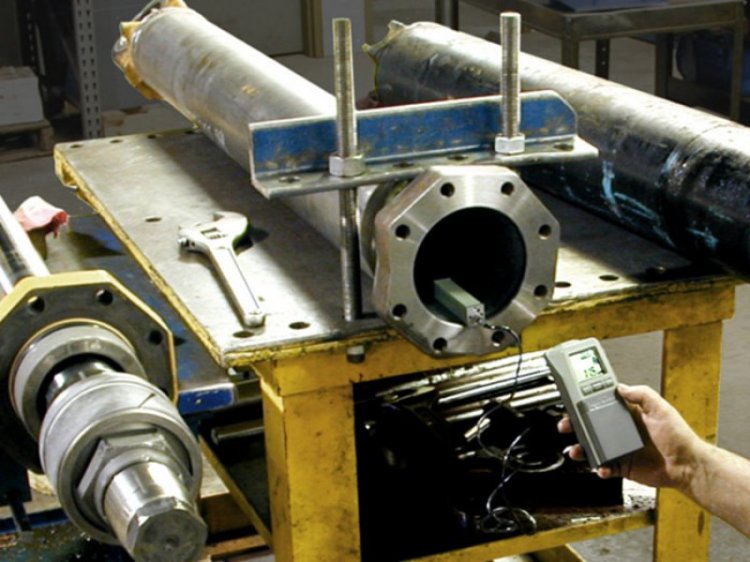

When considering if your hydraulic cylinder may be leaking, you can’t just rely on a visual inspection; instead it’s important to take into account all factors surrounding the condition and the way it operates.

How can you fix it?

There are a few things you can do if you suspect that your hydraulic cylinder is leaking. Take a close look at the hydraulics on your machine and notice if the oil or air bubbles seem like they are coming from any part of the system. If you see an oil or air bubble, then it is likely that there is an oil leak. You can try to fix this by checking for loose fittings or plugging up any holes where leakage could be occurring.

Preventative maintenance

The best way to know if your hydraulic cylinder is leaking is by performing regular preventative maintenance. Keep a watchful eye on the fluid level so that you can tell when the pressure drops below the normal line, and service or replace parts as needed.

Tips for cylinders with older seals

If your seal is leaking, chances are that the hydraulic cylinder isn’t getting pressurized when the control valve opens.

When you apply force on the plunger, you can see this leak by looking closely at the fluid just released from the cylinder and moving it in different directions with your hand.

To fix this, hydraulic ram repairs typically involve removing any old seals or worn parts of the housing to get a clean slate.